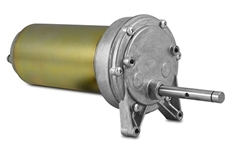

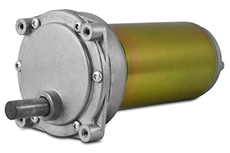

In-Line Parallel Shaft Gear Motors Delivering High Torque

Parallel Shaft Gear Motor refer to the position in which the gearbox reducer’s output shaft is sitting. If the motor shaft and the speed reducer output shaft are on parallel planes, that is considered “parallel shaft.” This position, coupled with the inline positioning, enables the gear motor to succeed in limited-space areas. Compact size leads to less weight, less sound, less vibration, and a happy customer experience.

Take a look at our unique inline parallel shaft gearboxes to see which one meets your operation’s strict stipulations. We have offerings for high-torque gear motor options or versatile yet powerful configurations.

Still can’t find what you’re looking for? Check out our custom gear motor section and contact us with the exact specifications you’re looking for. Chances are, we’ve already created a gear motor reducer quite similar to what you’re imagining.

Advantages of In-Line Parallel Shaft Gear Motor

Parallel shaft gear motors refer to the position in which the gearbox reducer’s output shaft is sitting. When the motor shaft and the speed reducer output shaft are on parallel planes, they are referred to as “parallel shaft” gear motors. This position, coupled with the inline positioning, enables you to use a flat gearbox. Parallel shaft DC gear motors offers advantages such as:

-

Compact design makes them ideal for areas with limited space.

-

Less weight and vibration.

-

Low noise levels for quiet operation.

-

Withstands high torque and strong radial forces.

-

Can reach a power rating up to 200 kW and nominal torque of 20,000 Nm for the speed reducer.

Parallel shaft DC gear motors operate using three types of gears:

-

Spur gears are made with straight teeth placed parallel to the drive shaft of the speed reducer and are the most widely used gear type. They are ideal for mechanical applications such as clocks, pumps, washers and dryers, and irrigation systems.

-

Helical gears contain teeth that are oblique (neither parallel nor perpendicular) to the axis of rotation. This allows them to transfer greater power and speed and makes them quieter and longer-lasting than other gears.

-

Double helical gears combine left-handed and right-handed helical gears to transmit rotational motion between two parallel shafts. In addition to having the same advantages as helical gears, they also eliminate axial thrust forces (rotation caused by the shaft).

Which gear you choose ultimately depends on your application. Parallel shaft DC gear motors are 90% efficient at dissipating heat. This makes them especially suited for continuous duty, low torque, and high ambient temperature applications.

Gearbox Solutions Perfect for You

Take a look at our unique inline parallel shaft gearboxes to see which one meets your operation’s strict stipulations. We have offerings for high-torque gear motor options, as well as versatile yet powerful configurations.

Still can’t find what you’re looking for? We offer custom parallel shaft gear motor solutions for operations of all sizes. Check out our custom gear motor section and contact us with the exact specifications you’re looking for. Chances are, we’ve already created a gear motor reducer quite similar to what you’re imagining. If not, our experienced engineering team will work with you to determine the best solution for your needs — or design a new one for your precise application.